- Design performed by qualified technocrats with support of updated software

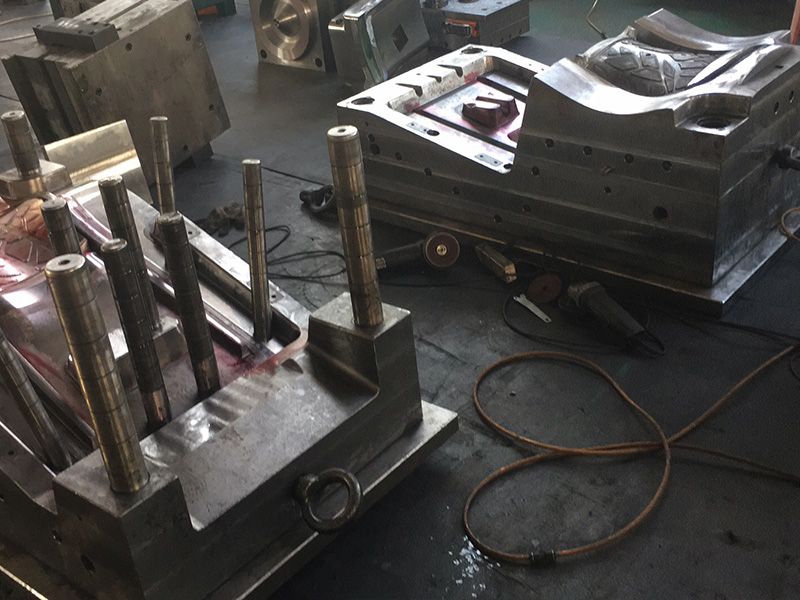

- Each Mould gets simulated by high end mould flow analysis software

- Mould steel CP20/718 Pre Hardened to achieve desired life

- Profiling done in high end CAM with latest high speed CNC Machines

- Pre Matching of Core & cavity , Slider by CNC Spotting machine to reduce manual involvement

- Adequate Wear resistive elements incorporated at specified places for enhanced Mould life

- High turbulent adequate cooling lines includes both parallel and cross cooling facility in order to achieve lowest cycle time

- Each mould leaves for customers with real time testing performed under customer’s specific processing parameters viz. locking force, injection speed & pressure against selected MFI of polymer

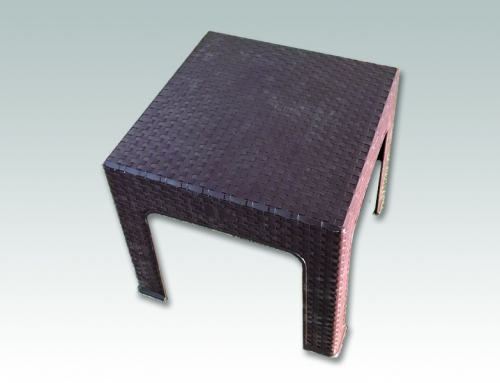

Premium Chairsadmin2018-07-31T14:18:29+00:00